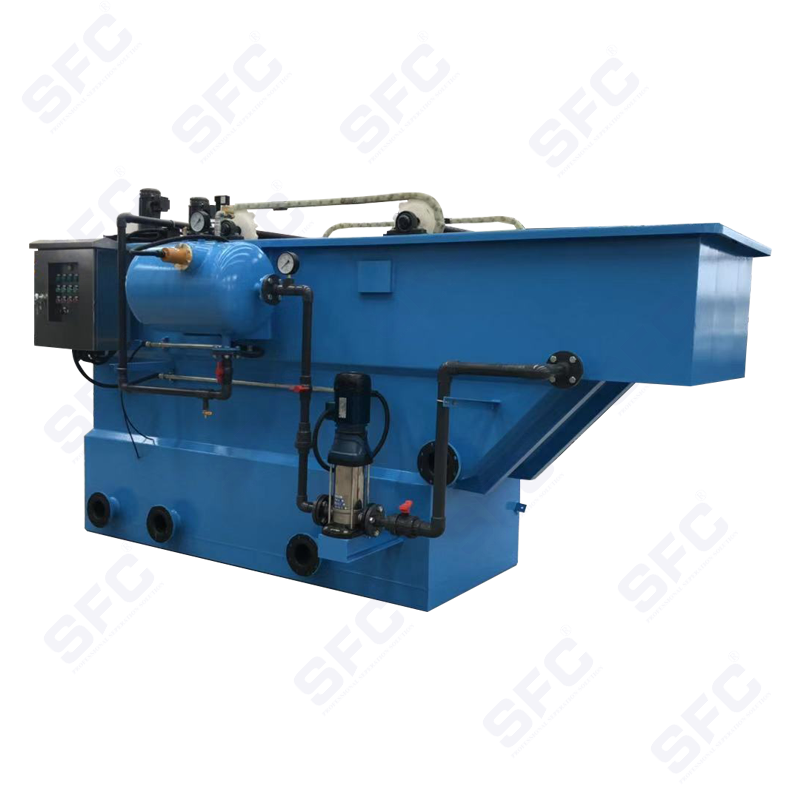

RDAF standard dissolved air flotation

Contact Us

Working Principle:

The treated effluent is taken as circulating water through a circulating pump and enters the dissolved air tank. At the same time, compressed air is added to the dissolved air tank, and efficient soda-water mixing is carried out in the dissolved air tank. After mixing, the dissolved air water containing air is sent to the air flotation contact area. The instantaneous pressure release through the releaser generates a large number of microbubbles, which quickly attach to the coagulated suspended matter. The density of the suspended matter is gradually less than the density of water, and it automatically floats to the surface. The water at the bottom of the equipment is left in a hurry, and it is discharged to the clean water area through the water outlet device at the bottom. Part of the water in the clean water area continues to be used as circulating water for the equipment, and the rest is discharged to the next process. The scum floating to the surface is scraped to the scum pool by the scraper for further treatment.

Product Advantages:

1. High efficiency: high processing efficiency, can treat a large amount of water in a relatively short time.

2. Strong adaptability: suitable for treating various types of water, including sewage, industrial wastewater, agricultural drainage, etc., suitable for various water quality conditions.

3. Easy to operate: relatively simple operation and maintenance, only need to clean the scum regularly and maintain the equipment.4. Small footprint: Compared with traditional sedimentation tanks and filtration equipment, it occupies a smaller area and is suitable for places with limited space.

5. Reduce the use of chemical agents: Compared with other water treatment methods, in some cases, the use of chemical agents can be reduced or avoided, reducing the impact on the environment.

6. The treatment effects on the initial turbidity of water and specific particulate matter will be different, and operation and maintenance require certain skills and experience, etc.

Application Areas:

1. Petrochemical, slaughter, food (oil removal, SS reduction, COD reduction)

2. Printing and dyeing, textiles, leather making (SS reduction, decolorization, COD reduction)

3. Papermaking, pharmaceuticals (SS reduction, COD reduction)

4. Tail water improvement (phosphorus removal, SS reduction)

5. Recycled water reuse (SS reduction, oil removal)

6. River landscape water (SS reduction, turbidity reduction)

7. New energy, precious metal recovery (SS reduction, fluoride removal)

8. Garbage leachate (reducing the back-end biochemical load)

9. Surface treatment (heavy metal removal, SS reduction)

If you have any questions, inquiries, or concerns, as China RDAF standard dissolved air flotation Suppliers and Custom RDAF standard dissolved air flotation Factory,our highly skilled and dedicated team of SFC professionals is always at your disposal, ready to offer prompt and reliable assistance and support.

Our footprints are around the world

-

FBT series belt type sludge thickener

FBT series belt type sludge thickener

-

FRDT series rotary drum sludge thickener

FRDT series rotary drum sludge thickener

-

SST series screw type sludge thickener

SST series screw type sludge thickener

-

Belt type sludge thickening and dewatering machine

Belt type sludge thickening and dewatering machine

-

FTB series rotary drum sludge dewatering machine

FTB series rotary drum sludge dewatering machine

-

FTE series rotary drum sludge dewatering machine

FTE series rotary drum sludge dewatering machine

-

DL series screw sludge dehydrator/ screw type sludge dewatering machine

DL series screw sludge dehydrator/ screw type sludge dewatering machine

-

GDY series belt sludge concentration and dewatering machine

GDY series belt sludge concentration and dewatering machine

-

SD-High pressure sludge deep dewatering system

SD-High pressure sludge deep dewatering system

-

LSD-High pressure sludge deep dewatering system

LSD-High pressure sludge deep dewatering system

-

ZSD-High pressure sludge deep dewatering system

ZSD-High pressure sludge deep dewatering system

-

SFC-DM sludge mixer

SFC-DM sludge mixer

English

English Español

Español