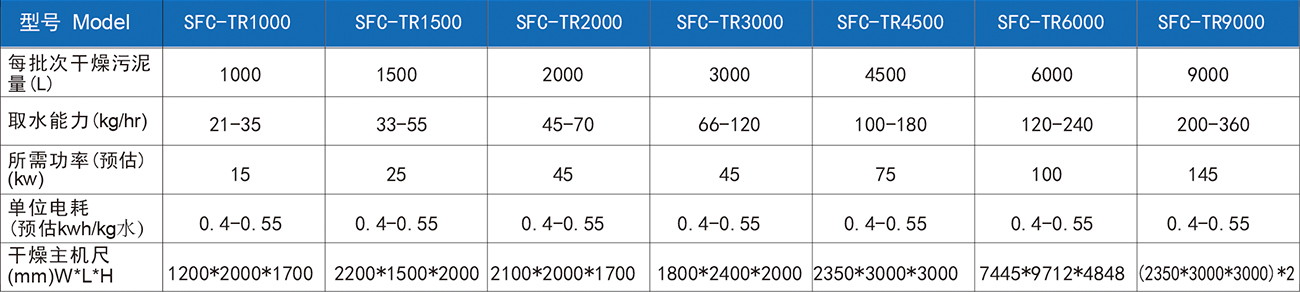

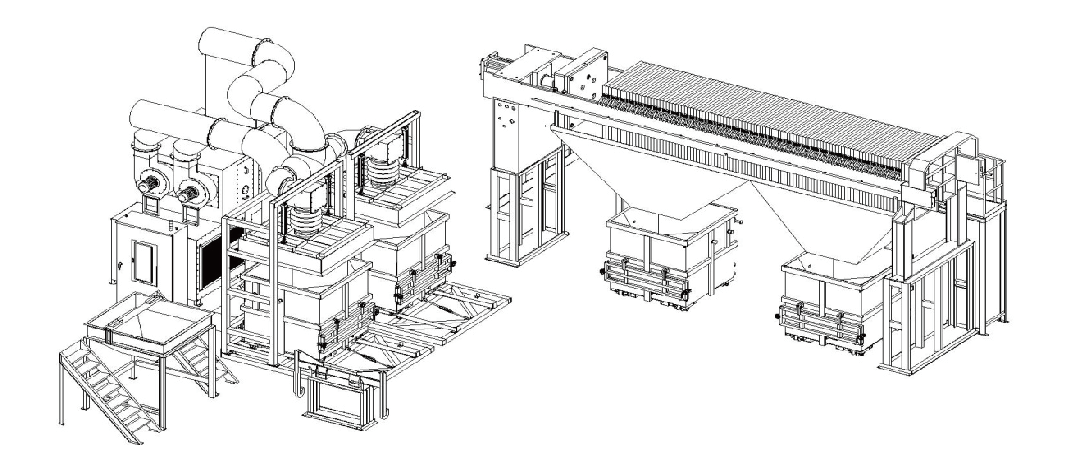

Reciprocating circular type sludge dryer

Contact Us

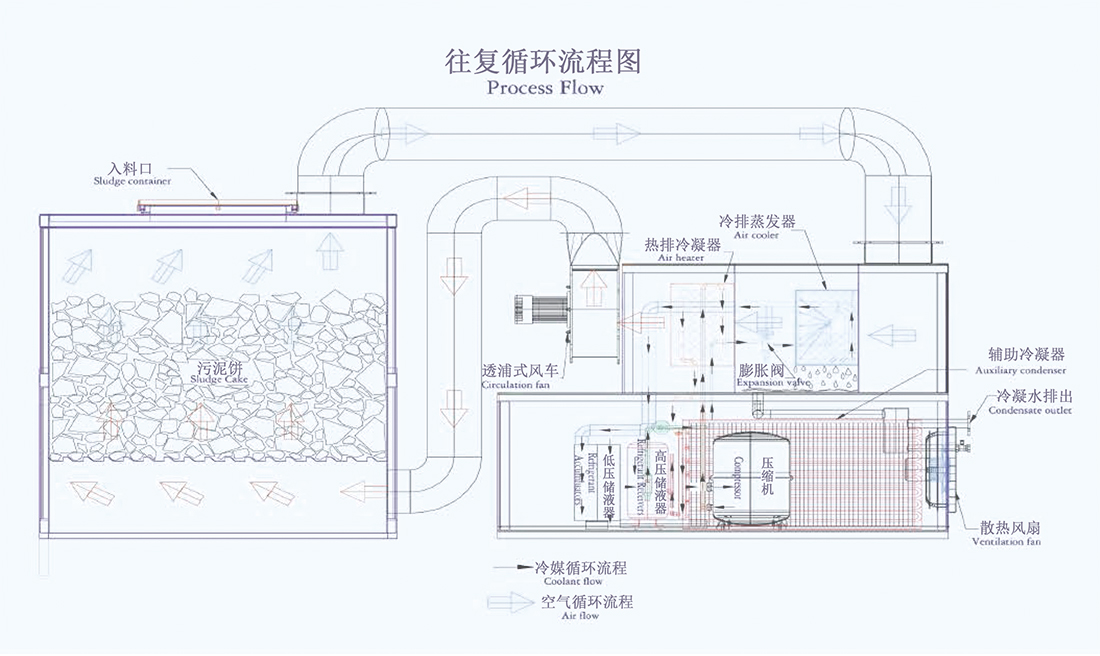

Working principle:

1、 The circulation of sludge dryer break the traditional sludge dewatering and then dry system, Energy is alternately circulated by two systems to discharge water to achieve reduce sludge .

2、Heat exchanger system generated heat to enhance the circulating air temperature, circulating air through the sludge, hot air make sludge moisture spread to the enclosed air, when the circulating air through the cold heat exchanger, the circulating air temperature decreases, the air moisture temperature drop. After the condensed dry air recirculate to the heat exchanger discharge.

Technical character:

1. Sludge can be reduced up to 70% after drying.

2. No emissions, no secondary pollution, low noise.

3. Save energy.

4. Integrated design, small footprint, save space.

5. Modular design, easy install.

6. PLC set the return air temperature automatically shut down.

If you have any questions, inquiries, or concerns, as China Reciprocating circular type sludge dryer Suppliers and Custom Reciprocating circular type sludge dryer Factory,our highly skilled and dedicated team of SFC professionals is always at your disposal, ready to offer prompt and reliable assistance and support.

Our footprints are around the world

-

FBT series belt type sludge thickener

FBT series belt type sludge thickener

-

FRDT series rotary drum sludge thickener

FRDT series rotary drum sludge thickener

-

SST series screw type sludge thickener

SST series screw type sludge thickener

-

Belt type sludge thickening and dewatering machine

Belt type sludge thickening and dewatering machine

-

FTB series rotary drum sludge dewatering machine

FTB series rotary drum sludge dewatering machine

-

FTE series rotary drum sludge dewatering machine

FTE series rotary drum sludge dewatering machine

-

DL series screw sludge dehydrator/ screw type sludge dewatering machine

DL series screw sludge dehydrator/ screw type sludge dewatering machine

-

GDY series belt sludge concentration and dewatering machine

GDY series belt sludge concentration and dewatering machine

-

SD-High pressure sludge deep dewatering system

SD-High pressure sludge deep dewatering system

-

LSD-High pressure sludge deep dewatering system

LSD-High pressure sludge deep dewatering system

-

ZSD-High pressure sludge deep dewatering system

ZSD-High pressure sludge deep dewatering system

-

SFC-DM sludge mixer

SFC-DM sludge mixer

English

English Español

Español