What is RDAF Dissolved Air Flotation and How Does It Work?

Understanding RDAF Standard Dissolved Air Flotation Systems

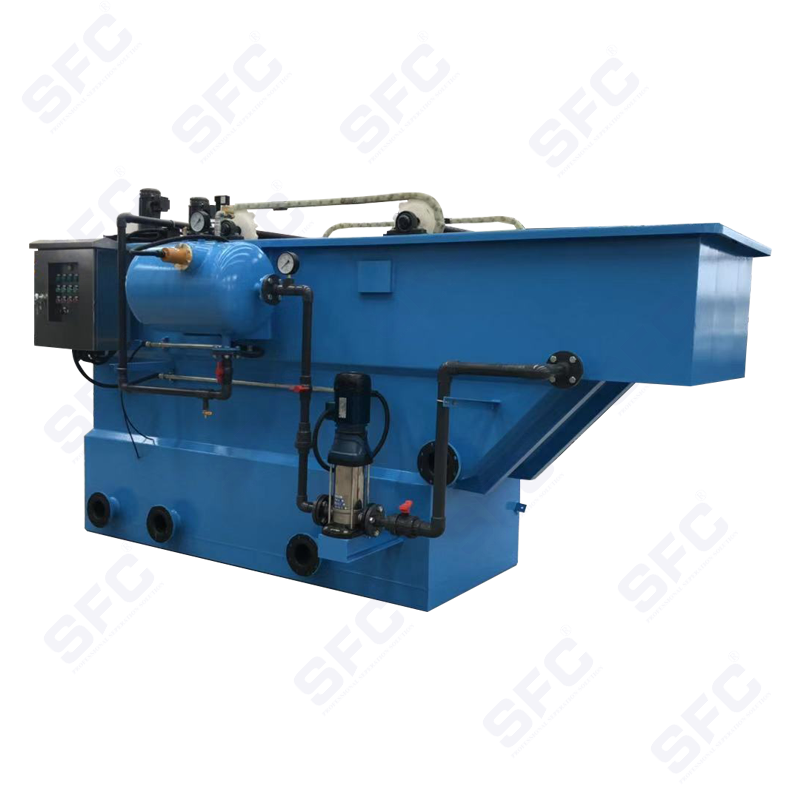

RDAF standard dissolved air flotation represents a proven water and wastewater treatment technology that utilizes microscopic air bubbles to separate suspended solids, oils, and other contaminants from liquid streams. The acronym RDAF stands for Rectangular Dissolved Air Flotation, distinguishing this configuration from circular or other geometric designs. This system operates by dissolving air under pressure in a recycle stream, then releasing it at atmospheric pressure in the flotation tank where the resulting microbubbles attach to particles and float them to the surface for removal. The rectangular configuration offers specific advantages in terms of hydraulic efficiency, footprint optimization, and ease of integration into existing treatment facilities.

The fundamental principle behind RDAF technology involves creating conditions favorable for bubble-particle attachment and subsequent flotation. When pressurized water saturated with air is introduced into the flotation tank through specially designed release devices, the sudden pressure drop causes air to come out of solution as extremely fine bubbles, typically ranging from ten to one hundred microns in diameter. These bubbles possess a strong affinity for suspended particles, especially when chemical coagulants and flocculants have been added to modify surface characteristics. The bubble-particle aggregates have a combined density lower than water, causing them to rise rapidly to the surface where they form a concentrated float layer that is continuously removed by mechanical skimming devices.

Key Components and Design Features

Flotation Tank Configuration

The rectangular flotation tank forms the central component of an RDAF system, typically constructed from reinforced concrete, coated steel, or stainless steel depending on the application and budget constraints. Tank dimensions are carefully calculated based on hydraulic loading rate, which typically ranges from four to twelve cubic meters per square meter per hour for municipal wastewater applications and may vary for industrial applications depending on specific contaminant characteristics. Length-to-width ratios generally fall between three-to-one and five-to-one to promote plug flow conditions and minimize short-circuiting, ensuring that all influent receives adequate contact time with the rising microbubbles.

Depth is another critical design parameter, with most RDAF tanks featuring water depths between two and three meters. This depth must accommodate several functional zones including the contact zone where bubbles and particles first interact, the separation zone where flotation occurs, and adequate freeboard to prevent float carryover during upset conditions. The tank bottom typically incorporates a slight slope toward the effluent end to facilitate settled solids removal, as some heavier particles may not float and instead settle to the tank floor despite chemical conditioning and bubble attachment opportunities.

Pressurization and Saturation Systems

The dissolved air generation system consists of several integrated components that work together to create the saturated pressurized water essential for flotation. A recycle pump draws clarified effluent from the flotation tank and pressurizes it to typically four to six bar, though some systems operate at higher pressures to achieve greater air dissolution. This pressurized water stream then passes through an air injection system where compressed air from a dedicated compressor or plant air system is introduced and mixed with the water. The air-water mixture flows into a pressurized retention tank or saturator vessel designed to provide sufficient contact time, usually thirty to sixty seconds, for the air to fully dissolve into the water according to Henry's Law principles.

Modern RDAF systems often employ packed-bed saturators containing specialized media that increase interfacial contact area between air bubbles and water, accelerating the dissolution process and allowing for more compact equipment. The saturator operates as a closed pressure vessel with level controls to maintain optimal liquid volume and ensure consistent saturation efficiency. Air-to-solids ratio, typically expressed as grams of air per gram of suspended solids removed, represents a critical operating parameter that operators adjust based on influent characteristics and target effluent quality, with typical values ranging from zero point zero one to zero point one depending on the application.

Release Mechanism and Contact Zone

The pressurized, air-saturated water enters the flotation tank through carefully engineered release devices that control bubble size distribution and ensure uniform distribution across the tank width. These devices, often consisting of needle valves, specialized nozzles, or proprietary baffle systems, create turbulence that promotes rapid mixing between the released microbubbles and the chemically conditioned influent stream. The contact zone immediately downstream of the release point is crucial for bubble-particle collision and attachment, with residence times typically ranging from thirty to ninety seconds. Some advanced RDAF designs incorporate recirculation zones or baffling arrangements that enhance contact efficiency and improve overall flotation performance.

Chemical Pretreatment Requirements

Successful RDAF operation almost always requires chemical conditioning of the influent to optimize particle characteristics for bubble attachment and flotation. The chemical treatment program typically involves coagulation followed by flocculation, using similar chemistry to conventional settling processes but with some important distinctions. Coagulants such as aluminum sulfate, ferric chloride, or polyaluminum chloride neutralize the electrostatic charges that keep particles in suspension, allowing them to come together. However, unlike settling applications where large, dense flocs are desired, RDAF systems benefit from smaller, lighter flocs with open structure that readily trap air bubbles and exhibit rapid rise rates.

Polymer selection and dosing play equally important roles in RDAF performance. Anionic or nonionic polymers are frequently employed to bridge between destabilized particles, creating floc structures with appropriate size and strength characteristics. The polymer must provide sufficient structural integrity to withstand the shear forces in the contact zone without creating overly dense aggregates that resist bubble attachment. Proper chemical conditioning requires careful attention to mixing intensity and duration, with flash mixing for coagulant addition followed by gentle flocculation that builds appropriately sized flocs without breaking them apart through excessive agitation.

Applications Across Different Sectors

| Application Sector | Primary Contaminants | Typical Removal Efficiency | Key Advantages |

| Municipal Wastewater | Suspended solids, BOD, phosphorus | 85-95% TSS, 60-80% BOD | Compact footprint, cold weather performance |

| Industrial Oil/Water | Petroleum hydrocarbons, grease | 90-99% oil and grease | Handles emulsified oils effectively |

| Food Processing | Fats, proteins, suspended organics | 80-95% TSS and FOG | Recovers valuable byproducts |

| Pulp and Paper | Fiber fines, ink particles, lignin | 70-90% TSS | Fiber recovery and reuse |

| Drinking Water | Algae, color, low-density particles | 90-99% algae removal | Superior algae and color removal |

Operational Parameters and Performance Optimization

Critical Control Parameters

Successful RDAF operation requires careful monitoring and control of several interrelated parameters that collectively determine system performance. Hydraulic loading rate must be maintained within design limits to ensure adequate bubble-particle contact time and prevent hydraulic overload conditions that cause poor separation and solids carryover to the effluent. Recycle ratio, defined as the flow of pressurized recycle water divided by influent flow, typically ranges from fifteen to fifty percent depending on influent characteristics and desired air-to-solids ratio. Higher recycle ratios provide more dissolved air but also increase energy consumption and may cause excessive turbulence that disrupts float layer formation.

Pressure in the saturation system directly impacts the mass of air dissolved per unit volume of recycle water, with higher pressures yielding more dissolved air but also requiring more energy for compression and stronger equipment to withstand the operating conditions. Most systems operate between four and six bar as a practical compromise between air dissolution capacity and equipment costs. Temperature affects both air solubility and water viscosity, with colder water capable of dissolving more air but also creating more viscous conditions that slow bubble rise rates and may require adjustments to chemical dosing or other operating parameters to maintain performance.

Float Removal and Sludge Management

The concentrated float layer that accumulates at the tank surface must be continuously removed to prevent it from becoming too thick and potentially breaking apart and re-entraining into the clarified water. Mechanical skimmers, typically consisting of rotating paddles, endless chain flights, or traveling bridges, sweep the float toward collection troughs or beaches where it drains and is pumped to downstream sludge processing facilities. Float solids concentrations generally range from two to six percent depending on the nature of the floated material, chemical conditioning effectiveness, and skimmer design, representing a significant volume reduction compared to the influent stream but typically requiring further thickening before final dewatering or disposal.

Advantages Over Alternative Technologies

RDAF systems offer several compelling advantages compared to conventional gravity sedimentation or other clarification technologies. The compact footprint requirements make them particularly attractive for sites with limited available space or high land costs, as flotation tanks typically require only twenty-five to forty percent of the surface area needed for equivalent capacity sedimentation basins. This space efficiency stems from the rapid rise rates of bubble-particle aggregates compared to the slow settling velocities of conventional floc, allowing higher hydraulic loading rates and shorter retention times while maintaining excellent effluent quality.

- Superior performance in cold weather conditions where low temperatures increase water viscosity and slow settling rates, but have minimal impact on flotation efficiency since bubble rise rates remain relatively constant across normal operating temperature ranges.

- Exceptional removal of low-density particles such as algae, fats, oils, and certain industrial contaminants that may never settle in conventional clarifiers regardless of detention time provided.

- Rapid startup and response to flow variations, with systems reaching steady-state performance within minutes rather than the hours required for sedimentation basins to establish proper sludge blankets and flow patterns.

- Production of thicker sludge compared to gravity settling, reducing downstream thickening requirements and associated costs for sludge handling and disposal.

- Flexibility to treat varying influent characteristics through adjustments to chemical dosing, recycle ratio, and air dissolution pressure without requiring physical modifications to the treatment system.

Maintenance Requirements and Best Practices

Proper maintenance is essential for reliable long-term RDAF performance and minimizing unplanned downtime. Daily operator rounds should include visual inspection of float characteristics including thickness, consistency, and uniformity across the tank width, which provide valuable insights into process stability and chemical conditioning effectiveness. Effluent clarity should be monitored continuously or at frequent intervals, with turbidity or suspended solids measurements providing early warning of deteriorating performance before permit violations occur. Operators should verify proper operation of the recycle pump, air compressor, and saturation system, checking for unusual noises, vibrations, or pressure fluctuations that might indicate developing mechanical problems.

Weekly maintenance activities typically include cleaning of air release devices to prevent plugging that can cause uneven bubble distribution and reduced flotation efficiency, inspection and lubrication of skimmer mechanisms according to manufacturer recommendations, and calibration verification of instrumentation measuring critical parameters such as pressure, flow, and chemical feed rates. Monthly tasks should encompass more detailed inspections of rotating equipment for wear or damage, testing of level controls and automatic shutdown systems to ensure proper function during emergency conditions, and review of performance data to identify trends suggesting need for adjustments to operating parameters or chemical treatment programs. The saturation tank requires periodic cleaning to remove accumulated solids that can reduce effective volume and saturation efficiency, with frequency depending on water quality and pretreatment effectiveness.

Troubleshooting Common Performance Issues

Operators occasionally encounter performance problems requiring systematic diagnosis and correction. Poor effluent quality characterized by high suspended solids or turbidity can result from numerous causes including inadequate chemical conditioning, excessive hydraulic loading, insufficient air supply due to compressor problems or saturator fouling, or mechanical issues with float removal systems allowing material to escape over the effluent weir. Addressing this requires methodical evaluation starting with verification of chemical dosing rates and jar testing to confirm optimal coagulant and polymer types and doses, followed by checks of hydraulic loading against design capacity, inspection of air delivery systems, and examination of skimmer operation.

Thin or poorly formed float layers suggest problems with bubble generation, chemical conditioning, or influent characteristics. Possible causes include air compressor malfunction reducing dissolved air availability, inadequate recycle ratio failing to provide sufficient bubbles for particle flotation, changes in influent composition that render the existing chemical treatment program ineffective, or extremely high influent solids concentrations overwhelming system capacity. Solutions may involve increasing recycle ratio or saturation pressure to boost air supply, adjusting chemical types or doses through systematic jar testing, or implementing flow equalization to dampen influent variations and maintain more stable operating conditions. In some cases, fundamental changes to the chemical treatment approach may be necessary, such as switching from metallic coagulants to polymers or vice versa depending on specific contaminant characteristics.

Energy Considerations and Sustainability

Energy consumption represents a significant operating cost for RDAF systems and an important consideration from both economic and environmental sustainability perspectives. The primary energy consumers include the recycle pump, which must overcome both static head and friction losses while delivering flow at elevated pressure, and the air compressor supplying compressed air to the saturation system. Total specific energy consumption typically ranges from fifteen to thirty kilowatt-hours per thousand cubic meters of water treated, varying with system design, operating pressure, and recycle ratio. This energy intensity generally exceeds that of conventional gravity settling but remains substantially lower than advanced treatment technologies such as membrane filtration.

Optimization opportunities exist to minimize energy consumption while maintaining required performance levels. Variable frequency drives on recycle pumps and air compressors allow output to match actual demand rather than running continuously at maximum capacity, potentially reducing energy use by twenty to forty percent during periods of lower flow or when influent characteristics permit operation at reduced air-to-solids ratios. Energy recovery devices such as hydraulic turbines can capture energy from the pressurized recycle stream before it enters the flotation tank, though economic justification requires careful analysis of installation costs versus potential savings. Some facilities have successfully implemented solar-powered air compression or utilized waste heat from other plant processes to reduce purchased energy requirements and improve overall sustainability metrics.

Future Developments and Emerging Technologies

Ongoing research and development efforts continue advancing RDAF technology through improvements in equipment design, process control, and integration with complementary treatment processes. Advanced process control systems incorporating real-time monitoring of multiple parameters and automated adjustment of chemical dosing, recycle ratio, and other variables based on predictive algorithms promise to optimize performance while minimizing chemical and energy consumption. Machine learning approaches analyzing historical performance data can identify subtle patterns and relationships that human operators might miss, enabling proactive adjustments that prevent upsets before they impact effluent quality. Integration of RDAF with membrane filtration in hybrid systems combines the strengths of both technologies, using flotation as an effective pretreatment that reduces membrane fouling and extends cleaning intervals while achieving exceptional overall treatment performance suitable for demanding applications including indirect potable reuse.

English

English Español

Español