What Maintenance Practices Are Essential for RDAF Standard Dissolved Air Flotation Units?

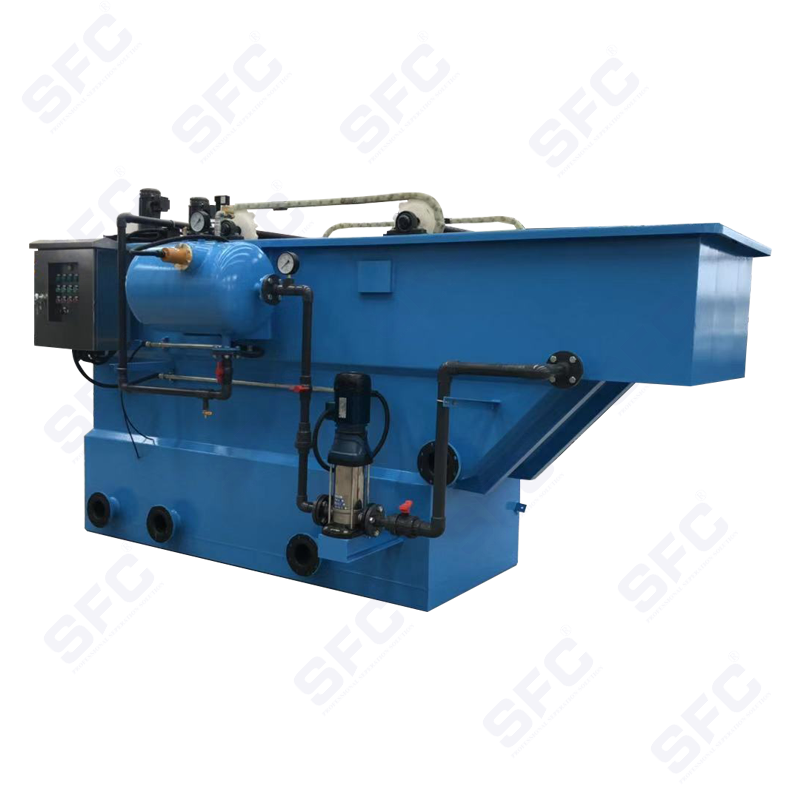

RDAF Standard Dissolved Air Flotation (DAF) systems play a critical role in modern wastewater treatment across industries such as food processing, petrochemical refining, textile dyeing, and municipal sewage. By efficiently removing suspended solids, oils, and greases from water using micro-bubble flotation, RDAF systems help facilities meet stringent discharge standards and improve downstream treatment efficiency.

While RDAF units are designed for robust, continuous operation, regular maintenance is essential to ensure consistent performance, minimize downtime, and extend the equipment’s lifespan. This article outlines the key maintenance practices that every plant operator or maintenance engineer should follow when managing an RDAF Standard Dissolved Air Flotation system.

1. Daily Inspection of Air Saturation System

The heart of any DAF system lies in its ability to generate highly saturated water containing fine air bubbles (typically 20–80 microns in size). This is achieved via the air dissolving system, which includes:

Saturation tank (pressure vessel)

Recirculation pump

Air compressor or injector

Pressure gauge and valves

Daily checklist:

Inspect the air compressor or venturi system for proper operation and airflow pressure.

Ensure the pressure in the saturation tank remains within optimal operating range (typically 4–6 bar).

Monitor for air leaks, back pressure, or unusual vibrations in the recirculation pump.

Check safety valves and pressure relief devices for compliance and wear.

A decline in air bubble generation will directly affect flotation efficiency, leading to poor sludge removal and higher turbidity in the effluent.

2. Sludge Scraper System Maintenance

RDAF units feature mechanical sludge scrapers (surface skimmers) that collect floated sludge from the water surface and direct it to a sludge hopper or discharge outlet.

Maintenance tasks:

Check the alignment and tension of scraper chains or belts.

Lubricate chain sprockets and drive bearings regularly (usually weekly or monthly depending on runtime).

Inspect scraper blades for wear, cracks, or detachment.

Clean any solids buildup on the scraper arms, surface weirs, and discharge troughs.

Neglected scraper systems may lead to accumulated sludge, which reduces surface clarity and can cause overflow or blockages.

3. Floatation Tank and Baffle Cleaning

The main flotation chamber must remain clean and free of biological growth or scaling to maintain flow uniformity and bubble dispersion.

Cleaning schedule:

Perform a visual inspection of the tank interior weekly for sludge deposits, oil films, or scaling.

Clean or brush the diffusers, baffles, and lamella plates (if equipped) monthly.

In high-load applications (e.g., slaughterhouses, oil refineries), conduct quarterly shutdowns for deep cleaning.

Drain and flush the tank with low-pressure water during preventive maintenance.

Fouled tank walls or submerged parts reduce the residence time and can interfere with laminar flow, affecting flotation efficiency.

4. Instrumentation and Control System Checks

RDAF units are often equipped with automated control panels, sensors, and level indicators for optimized operation.

Inspection protocol:

Test level sensors, turbidity meters, or flow switches weekly for accuracy.

Inspect electrical control panels for loose wires, moisture ingress, or error alarms.

Verify the settings for recirculation timing, scraper interval, and chemical dosing (if automated).

Update firmware or backup operational data as needed.

Reliable instrumentation ensures the unit reacts correctly to changes in influent quality or flow conditions.

5. Chemical Dosing System Maintenance (if applicable)

Many DAF systems use coagulants or flocculants (e.g., PAC, alum, or polymers) to improve solid agglomeration before flotation.

Key maintenance tips:

Clean and calibrate dosing pumps and flow meters monthly.

Flush chemical lines to prevent clogging and crystallization.

Check mixing tanks, agitators, and storage containers for residue buildup.

Monitor chemical usage trends and adjust for seasonal influent variability.

An unstable chemical dosing system can drastically reduce DAF performance and increase operating costs.

6. Effluent and Sludge Outlet Monitoring

The performance of the RDAF unit is only as good as its outlet quality. Poor performance may indicate internal issues.

What to monitor:

TSS (Total Suspended Solids) in effluent — should meet regulatory targets (typically <30 mg/L).

Sludge concentration and thickness — adjust scraper intervals accordingly.

Look for carryover or "pin floc" (small flocs passing into effluent) which may indicate air saturation or chemical dosing issues.

Install sample ports and sight glasses to allow for regular quality checks.

7. Structural and Mechanical Component Maintenance

Though often overlooked, the RDAF’s structural integrity ensures long-term safety and function.

Recommendations:

Inspect tank walls, support beams, and railings for corrosion or cracks.

Tighten any loosened bolts, anchors, or brackets.

Repaint or recoat internal surfaces every 2–3 years to prevent corrosion.

Ensure sludge hoppers, effluent troughs, and drain valves are operating smoothly.

If the RDAF system includes lamella packs, inspect for clogging, cracking, or shifting — as misalignment can affect flow patterns.

Why Proactive Maintenance Matters

Maintaining your RDAF Standard Dissolved Air Flotation system doesn’t just protect your investment—it also:

Improves water discharge quality

Reduces energy and chemical consumption

Minimizes unplanned downtime

Extends equipment lifespan by 5–10 years

Ensures safety and environmental compliance

Neglected systems often suffer from reduced flotation performance, higher sludge moisture content, and increased back-end treatment loads.

RDAF Standard DAF systems offer advanced flotation performance, especially when handling high-solids wastewater or oily effluents. However, to maintain peak performance, operators must adopt a structured and proactive maintenance program. From air saturation checks to scraper alignment and instrumentation calibration, each maintenance activity plays a crucial role in ensuring system reliability and process efficiency.

English

English Español

Español